Arens Rohrleitungsbau

Ihr zuverlässiger Partner für den Anlagen- und Rohrleitungsbau, Schweißverfahren und Installationen

Leistungen

Aufgaben

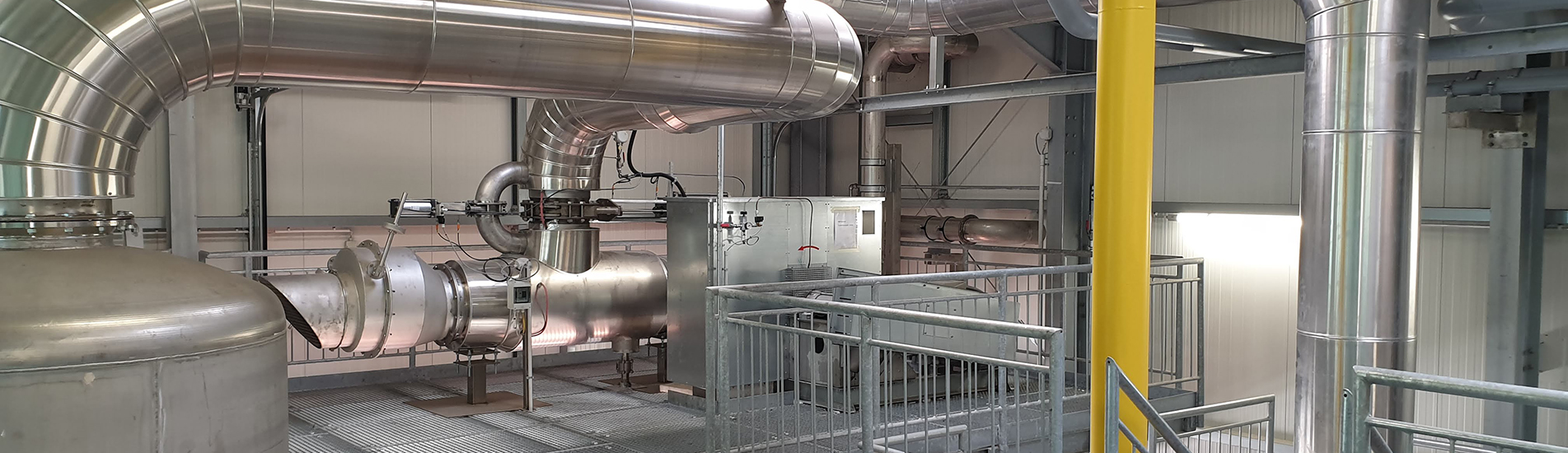

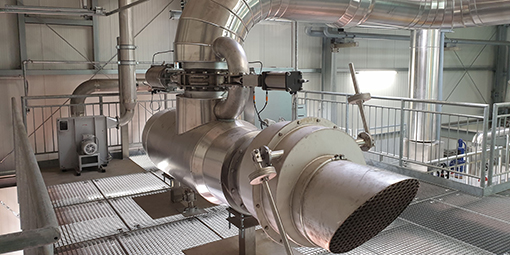

Wir unterstützen unsere Kunden aus der Industriebranche fachkundig und zuverlässig in den Bereichen Anlagenbau, Rohrleitungsbau, Schweißverfahren, Installationen und Reparaturen.

Kompetenzen

Fachlich hochqualifizierte Mitarbeiter bilden die Grundlage für die erfolgreiche Erledigung von Aufträgen und sorgfältige Durchführung von Projekten.

Die Fertigkeiten unserer Mitarbeiter sind eingebettet in tiefgehende betriebliche Kenntnisse in den Bereichen verschiedener Schweißverfahren.

Branchen

Als verlässlicher Partner genießen wir das Vertrauen vieler Unternehmen unterschiedlichster Industriezweige.

Mit unserem branchenspezifischen Know-how helfen wir gerne auch Ihrem Unternehmen bei kommenden Projekten.

News

Referenzen

Für unsere vielfältigen Kunden realisieren wir herausragenden Projekte. Beim Klick auf den Button erfahren Sie mehr darüber, in welchen Branchen und Bereichen wir bereits tätig werden durften.

Zertifikate

Arbeitsprozesse, Produkte oder Systeme verlangen oftmals die Erfüllung bestimmter festgelegter Anforderungen. Durch unsere Zertifikate weisen wir ein rechtssicheres Qualitätsmanagementsystem nach.

über

Langjährige

Mitarbeiter

mehr als

Zufriedene

Partner

über

Realisierte

Projekte

mehr als

Jahre

Erfahrung

Arens Rohrleitungsbau

Seit über 50 Jahren versteht sich Arens Rohrleitungsbau als professioneller Partner von Unternehmen aus der Industrie und als verlässlicher Arbeitgeber von über hundert Mitarbeitern. Dabei sind wir ein Familienunternehmen geblieben.

Klassische Werte wie Qualitätsbewusstsein, Termintreue, Ehrlichkeit und Verlässlichkeit zeichnen uns aus – genauso wie faire, transparente Angebote und hohe Flexibilität. Die meisten unserer Kunden sind seit vielen Jahren an unserer Seite und dafür sind wir sehr dankbar.